Focusing on the two emerging markets of new energy vehicles and industrial energy storage, Datang NXP recently launched a new battery management system (BMS) chip DNB1101A for industrial energy storage system applications, which can provide a variety of sensing functions for each individual cell or a group of cells in parallel, including voltage monitoring, temperature monitoring and electrochemical impedance spectroscopy (EIS) monitoring.

As we all know, compared with electric vehicles, industrial energy storage technology has the same strict requirements for battery management chips in terms of high performance, stability and safety. Therefore, the ability to measure the electrochemical impedance spectrum of the battery online in a wide frequency range has become one of the core highlights of DNB1101A.

Elvin Hermon, CTO of Datang NXP Semiconductor Co., Ltd., said in an interview with electronic engineering album that the EIS function integrated in DNB1101A has the ability to measure the electrochemical impedance of the battery at different frequencies with very high accuracy, and can obtain the in-depth safety information of the internal state of the battery such as overheating risk, lithium evolution degree and aging degree through further calculation, It can also establish the basis for further battery performance optimization, such as obtaining higher power, faster charging efficiency, improving mileage, etc.

So far, EIS measurement can only be carried out with relatively large equipment in the laboratory. However, DNB1101A integrates the EIS function directly on the chip, and the chip can be integrated on the battery electrode or even inside the battery to realize the on-line EIS monitoring of the system.

"Through the high integration of on-chip EIS and system, we have achieved better battery performance, higher security level, less system BOM cost and simpler BMS system. In fact, compared with any other system currently used in the industry, our system can early warn the failure of battery units, which is very critical." Elvin Hermon said.

In addition, DNB1101A also integrates a temperature sensor on the chip for cell temperature measurement, which eliminates the need for external thermistors and their peripheral circuits, which is conducive to optimizing the system BOM, and each logic cell has temperature monitoring coverage, which is conducive to better temperature consistency in the battery pack. In terms of reliability, Datang NXP promises to strictly abide by the reliability appraisal standards and ensure that DNB1101A fully meets the specification requirements within its 15 year service life.

As a single battery BMS product, as the name suggests, DNB1101A only monitors and manages one battery unit. "This is a conscious choice to ensure that our BMS products are close to each unit." Elvin Hermon explained, "This proximity is very important to more accurately measure the impedance (EIS function) and eliminate the complexity of the whole battery (reduce BMS electronic board, connector, cable...)." in this way, our chip only needs few external components, and all electronic components can be placed directly on the top of the battery, so as to improve the energy density of the battery pack and reduce the system cost. "

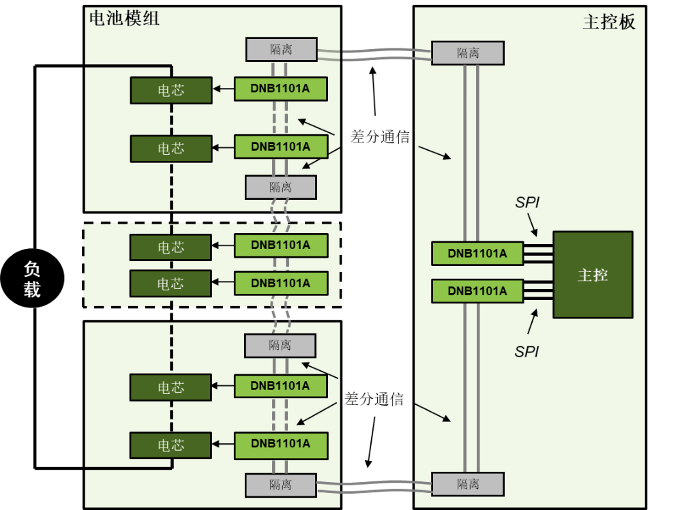

In BMS system, multiple DNB1101A are connected together through differential bus, and all data collected by cells can be provided to the central computing system. At the same time, DNB1101A integrates rich diagnostic functions, supports battery overvoltage, undervoltage, overtemperature and low temperature alarms, as well as chip related abnormal alarms, and provides two equalization methods: internal equalization and external equalization. The equalization commands are programmed by the central computer through the differential bus, and DNB1101A will perform the equalization operation according to these commands.

DNB1101A system application block diagram

In terms of performance, DNB1101A provides an extraordinary measurement signal-to-noise ratio for EIS measurement, so it can be used for very low ohm high-capacity batteries; For voltage and temperature measurement, DNB1101A is designed to accurately measure all mainstream batteries (including NCM and LFP batteries); The differential daisy chain communication mode can support up to 250 series of cells in a single chain, and all sensing data can be quickly transmitted back to the main controller within a few milliseconds.

Two emerging markets with innovation

When talking about why new energy vehicles and industrial energy storage are the two major markets that Datang NXP focuses on, Elvin Hermon said that with climate change and the radical goals set by the group of 21 (cop21), the automotive industry needs to accelerate its development in the direction of sustainable transportation. In order to reduce pollution and climate change, the development of electric vehicles is accelerating all over the world, especially in China. Among them, battery efficiency (driving range) and cost (battery is still the most expensive part in the car) have become the decisive factors.

At the same time, demand in the industrial sector is also growing rapidly, especially for applications that provide energy support for renewable energy storage, grid / off grid, servers and telecommunications base stations. For example, with the emergence of 5g, the new requirements need to ensure that the relevant infrastructure can continue to operate even in the event of power supply interruption.

In fact, from a technical point of view, new energy vehicles and industrial energy storage are very similar in electronic monitoring and battery management: both involve voltage and temperature monitoring to ensure the safe operation of batteries; Are related to equalization to ensure that the power of each battery is consistent; They also pay attention to EIS measurement, hoping to achieve faster charging, more accurate health state description and higher safety.

"The realization of all these above requires innovative battery systems and BMS devices." Elvin Hermon pointed out, "in the future, one of the technical trends in the field of AFE IC will be to establish in-depth battery status information based on innovative sensing technology according to increasing safety requirements. Therefore, another trend will be the evolution of system hardware and software architecture to realize value chain integration."

In recent years, the local transfer trend of well-known semiconductor manufacturers is obvious. Moreover, even in China, the competition among peers is equally fierce. Therefore, if Datang NXP wants to gain a firm foothold in the fierce competition, what effective coping strategies it will adopt in terms of technology and product roadmap in the future is quite interesting.

In response, Elvin Hermon said that the mission of Datang NXP is to provide innovative and unique value battery management chip products and solutions for the electric vehicle and energy storage industry. In fact, Datang NXP is a market leader in EIS sensing technology - it has not only completed the on-chip integration of EIS IP, enabling battery system developers to understand the in-depth state of the battery, optimize the use of the battery, improve the power limit of the battery, predict the safety risk in the early stage, but also developed other core IPS, And all IPS can work together in a very complex battery system environment. With advanced BCD wafer technology, mature development process and iso26262 certification of the highest security level, Datang NXP is confident to become the preferred partner of customers.

However, the development of things has never been smooth sailing. Even Datang NXP, which has two core shareholders of Datang and NXP, is no exception. The shortage of talents and chips once caused great pressure on the development of the company.

Elvin Hermon told reporters that designing mixed signal integrated circuits requires the best and most experienced engineers, and all companies are trying to attract these rare talents. The company did experience some unnecessary losses and lost some designers who developed new products. Fortunately, while trying to attract talents, Datang NXP has multiple R & D centers around the world. When one place is facing difficulties, the company will try to use other resources to continue its R & D work.

"Yes, we also see the pressure of IC shortage. Chip manufacturing capacity, including front-end and back-end, is very critical." However, he said that thanks to the professional operation team, Datang NXP has signed manufacturing service agreements with a number of manufacturers, which can support each other. At the same time, considering that the current situation of insufficient capacity will continue for a long time, the company is also actively establishing additional capacity guarantee mechanism to alleviate the risks from the supply chain.