This winter seems even colder than usual. "In the blink of an eye, 23 years have entered their final month. Electric vehicles are facing the same winter challenge as before. Compared to the intuitive feeling of temperature, for electric vehicle owners, it is not only the weather that brings coldness, but also the anxiety of the battery of their purchased electric vehicle.

Recently, there have been heavy snowstorms in the north, and it is another cold winter. New energy vehicle

owners are facing unprecedented energy consumption challenges Due to the poor performance of current

battery technology in low-temperature environments, the vehicle's range has significantly decreased, coupled

with the use of winter air conditioning, resulting in a false indication of battery power. New energy vehicle

owners are looking for charging facilities one after another, but during low-temperature charging, due to the

increased internal resistance of the battery at low temperatures, the insertion of lithium ions on the graphite

electrode of the battery and the lithium plating reaction coexist and compete with each other. Under low

temperature conditions, the diffusion of lithium ions in graphite is suppressed, and the conductivity of the

electrolyte decreases, resulting in a decrease in the insertion rate. This makes the lithium plating reaction

easier to occur on the surface of graphite. Ultimately, it leads to a decrease in charging rate and affects the

battery's lifespan. The main reasons for the decrease in lifespan of lithium-ion batteries when used at low

temperatures are the increase in internal impedance and the capacity degradation caused by lithium ion

precipitation. Therefore, charging and discharging at appropriate internal resistance and temperature can

greatly improve battery lifespan.

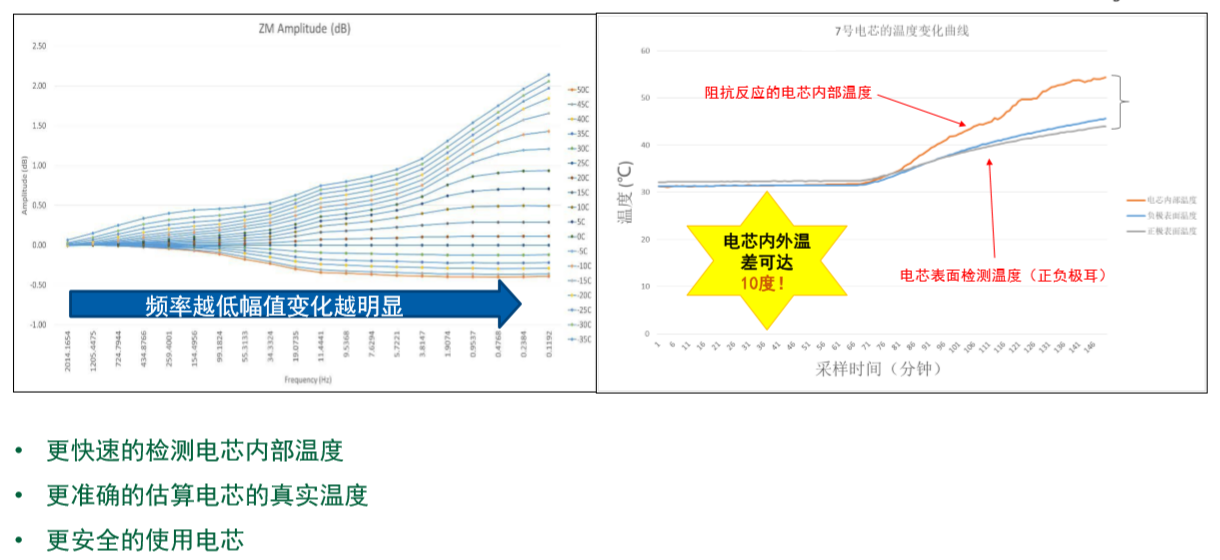

The battery management system of Datang NXP can quickly and effectively detect the current internal

resistance (in seconds) of the battery, thereby estimating the internal temperature of the battery. In addition,

its single cell architecture can achieve full temperature coverage of each cell, achieving dual temperature

assurance, which can enable the battery to operate within a more suitable temperature range, effectively

ensuring battery stability and improving battery life.

01 Battery Management System

DNB1168 is a globally leading single-cell monitoring chip with integrated (EIS) AC impedance spectroscopy monitoring

function.The chip has passed dual certification of AEC-Q100 automotive grade and ISO 26262:2018 ASIL-D, the highest

functional safety level in the automotive industry. The chip integrates multiple high-precision battery parameter monitoring functions internally, supporting voltage, temperature, AC impedance detection, balancing, and various fault diagnosis functions. It can provide exclusive battery online "CT" detection technology worth hundreds of thousands of yuan for batteries, providing a new detection dimension for battery management systems and realizing health monitoring of the entire life cycle of batteries.

02 Practical Application in Winter

In the low temperature weather of Blizzard, if the temperature drops below 0 ℃, the discharge capacity of ordinary lithium

batteries will correspondingly decrease, causing the power to disappear by half when the switch is turned off.

In addition, data shows that the capacity of ordinary lithium batteries will decrease by 20% at 0 ℃; When the temperature

reaches minus 10 ℃, the capacity may only be about half. Moreover, the lower the temperature, the poorer the ionization

activity of the battery, which will lead to a decrease in charging efficiency, known as "difficult charging and low capacity",

and greatly increase battery life anxiety.

In practical applications, in order to allow customers to charge even when the temperature is below 0 ℃, the vast majority

of electric vehicles are equipped with battery heating function. When the car owner inserts the charging gun, first heat

the battery to a temperature above 0 ℃ before starting charging.

Therefore, in the low temperature of winter, higher requirements are put forward for battery temperature monitoring and

insulation in low-temperature environments.

03 Fast Charging and Thermal Insulation in Winter

The use of lithium batteries in low-temperature environments is limited. In addition to severe degradation of discharge

capacity, using batteries at low temperatures can also lead to a decrease in battery life. The low temperature in winter

also means that the system needs more electricity to keep the battery warm.

In the low temperature of winter, Datang NXP provides an effective solution to the severe challenges faced by batteries!

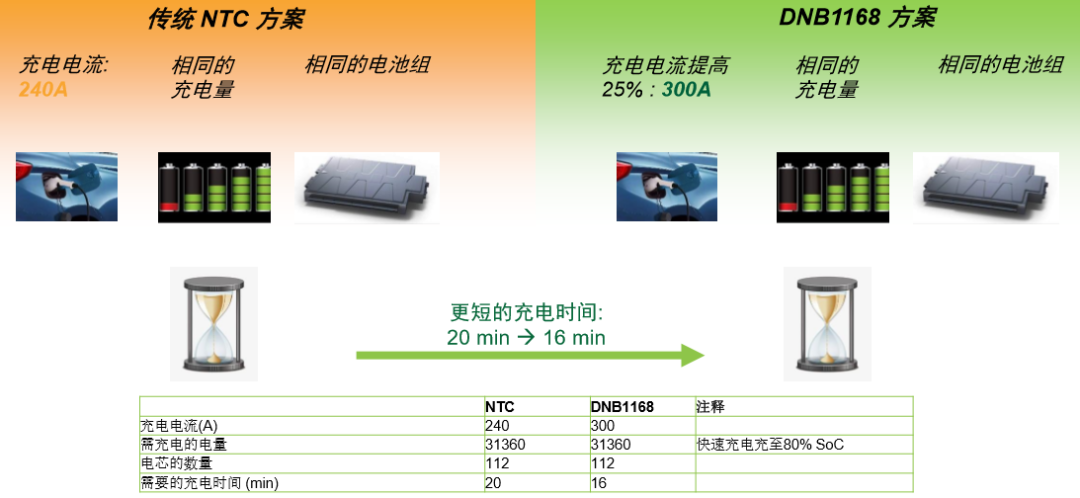

The Datang NXP DNB1168 battery management system has an internal temperature estimation function, which can

quickly heat up the battery before low-temperature charging, shorten the heating time, reduce heating and insulation

energy consumption, and ensure that the battery can always work within the optimal temperature range

In addition, charging will cause the battery temperature to continue to rise, and the charging power will also increase

accordingly. Therefore, for electric vehicles in winter, it is very important to be able to quickly determine temperature

changes during use.

The DNB1168 battery management system of Datang NXP can quickly and accurately estimate the internal temperature

of the battery in low-temperature environments, provide early warning, and dare to increase the charging and discharging

current. No matter what situation occurs, the system can quickly make strategic responses. It can also keep the battery at

a suitable working temperature, avoiding an increase in resistance, a decrease in capacitance, and a reduction in mileage

in low-temperature environments.

If the hidden dangers of power battery range and stability cannot be completely solved for the public, no matter how

good or advanced the marketing is, it cannot sustain the brand development in the long run. Datang NXP's battery

management system not only achieves the ultimate in safety, but also is definitely a leader in performance and intelligence

in the industry, making the internal management of batteries orderly. Professional battery cells and chip development

far beyond national standards provide consumers with more reassuring batteries!