With the rapid development of the new energy industry, various types of new energy, mainly lithium batteries, have

penetrated into all aspects of society, with increasingly wide usage scenarios. More and more large-scale energy

storage power stations, industrial and commercial energy storage, and household energy storage are built every year,

and new energy vehicles are becoming more and more popular. Even a new energy vehicle launch event can attract

public attention, indicating that new energy, mainly lithium batteries, has become an important cornerstone of social development.

But with the widespread use of lithium batteries, some safety issues are occasionally exposed. This is also because people

can no longer leave new energy, and they always maintain a high level of attention to such safety related accidents. In this

situation, no new energy manufacturer is willing to become the focus of negative news. Efforts to improve their own hard

power, develop new energy related technologies, accurately estimate safety risks, and ensure the safe use of new energy

are the visions of every new energy manufacturer.

To ensure the safe use of lithium batteries,

New energy manufacturers not only need to focus on battery cell research and development, design

Put effort into production and manufacturing,

Attention to Battery Management System (BMS)

It is also increasing day by day

1、 BMS (Building Management System)

BMS can be divided into two parts as a whole: hardware and software.

BMS hardware

The BMS hardware includes an analog front-end sampling chip (AFE) and a microcontroller chip (MCU),

AFE is responsible for collecting various characteristic data of the battery, including voltage, temperature, etc.

The MCU is responsible for local control and computation, processing the data collected by the AFE, managing the battery

cells using simple algorithms and control logic, or uploading the data to the cloud for remote monitoring and more complex

algorithm calculations.

BMS software

BMS software mainly consists of embedded software running on the MCU end and monitoring terminals running on the

cloud platform. Embedded software can process small amounts of data and make some simple logical judgments, while

more complex data processing and control are usually handled by the cloud platform

The data collected by AFE will affect the accuracy of the backend software control strategy. The higher the accuracy and

richness of the data collected by AFE, the more accurate the software control strategy will be.

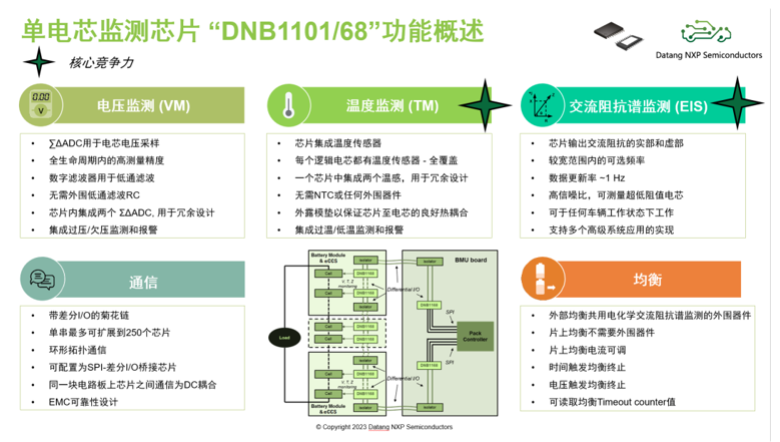

Datang NXP's advanced AFE products not only achieve industry-leading voltage and temperature detection accuracy,

but also integrate online electrochemical impedance spectroscopy (EIS) detection function, which directly expands several

dimensions of the detectable characteristic data of the battery, making the advanced functions of the backend software

more abundant, and the judgment logic and control strategy more accurate..

EIS has a wide range of application value in the field of electrochemistry

Can be used to study electrode materials for batteries

The dynamic process of electrode reaction, battery performance evaluation

Real time online estimation of state of charge and aging degree

Advanced safety warning and other aspects.

But we will encounter the following challenges:

Challenges faced by EIS applications

1. System related R&D engineers need to have strong expertise in electrochemistry

2. Need to utilize various professional analysis tools and corresponding software platforms

3. The algorithm design based on online communication impedance spectroscopy detection technology is complex

and has a long development cycle

4. The algorithm has limited deployable platforms and high requirements for computing power and other resources

5. In the early stage, various types of battery cells need to undergo long-term calibration work and collect a large

amount of data

In the face of these challenges, Datang NXP's innovative achievement: the sub-health battery cell 6D detection algorithm

(hereinafter referred to as the algorithm) that integrates EIS can perfectly solve the above difficulties, allowing end customers

to quickly and easily use online EIS detection technology.

2、 6D detection integrated with EIS

This algorithm needs to be used in conjunction with the Datang NXP DNB11 series AFE chip. The following is an introduction

to the algorithm:

The 6D detection included in the algorithm refers to the voltage, temperature, real and imaginary parts of EIS, EIS amplitude,

and EIS phase of the battery cell.

The sub healthy battery cell detection algorithm that integrates EIS performs comprehensive detection and judgment on

the battery cells in these six dimensions. When one or more feature values change, the algorithm can accurately capture

the outlier cell numbers and provide outlier alarm indicators.

Voltage and temperature: These two are important battery characterization data, both indispensable but not sufficient

because they are difficult to reflect some changes inside the battery cell, such as lithium deposition, mechanical damage,

etc.

EIS can precisely compensate for this data and achieve a more comprehensive detection of batteries from the inside out.

The value brought by this algorithm is also very obvious

EIS can be applied more quickly and effectively

Economic adaptability and value realization of 6D detection algorithm integrating EIS

1. The difficulty of algorithm development and design is very low, and engineers do not need deep programming and

development skills to use it flexibly. The development cycle is short, which can quickly promote the product to the market.

2. Developers do not need to have relevant electrochemical expertise to fully utilize the detection capabilities of algorithms.

3. The algorithm has very low resource requirements, and all commonly used 32-bit MCUs on BMS can run with fast detection

and judgment speed.

4. The algorithm can be deployed on multiple platforms, including cloud platform, local monitoring platform, edge computing platform,

BMS embedded platform, etc., to meet various application scenarios and different needs of customers.

5. The algorithm adapts to various types of cells and modules, without the need for various calibration work on the cells in the early stage,

nor does it require a large amount of data for pre training, greatly reducing the workload of system manufacturers.

6. Algorithms can be applied in various scenarios, such as consistency screening on battery cell production lines, real-time online monitoring

after pack grouping, and meet the needs of various working conditions.

7. Algorithms can detect cells with poor physical condition in the early stages of cell failure and continuously monitor

their health status to ensure overall health consistency.

By using this algorithm

End customers can

Better application of online EIS detection function

Launch products with strong competitive advantages faster

Quickly seize the market!

3、 Introduction to Algorithm Ideas

The idea of 6D detection algorithm for sub-health battery cells integrating EIS:

Process the data to eliminate differences in attributes between different variables, treating each cell as a point in six dimensions.

Use clustering algorithm to classify all battery cells into clusters and obtain the centroid of each cluster.

By calculating the distance between each point and the centroid, the algorithm determines the outlier situation of the

point. When it exceeds a certain threshold, the algorithm will provide the outlier cell number and alarm indication.

-END-

Ensure the safe use of lithium batteries

BMS plays a crucial role

Innovation achievements of Datang NXP:

6D detection algorithm for sub-health battery cells integrated with EIS

Can accurately estimate security risks

Ensure the safe use of new energy

To enhance the competitiveness of new energy manufacturers' products

Behind every breakthrough in technology and product

Our original intention is to create a better experience for users

In 2024, we look forward to continuous innovation

For the development of new energy batteries

Bringing more reassuring protection

contact us

If you want to learn about the chips of Datang NXP, you can contact us in the following two ways:

1. Leave your contact information on the WeChat official account.

2. Send an email to: salesinfo@datangnxp.com .